by Li Liang, lli91@vt.edu

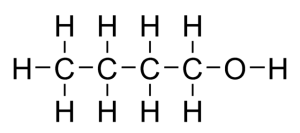

Renewable energy sources is an attractive option for ensuring future energy security (Sharma et al 2013), since it can reduce the fossil fuel dependency and mitigate climate change (Cherubini et al 2011). Therefore, researchers devote a lot to study and develop new energy, such as ethanol and biodiesel. However, a very potential overlooked energy substitute is bio-butanol (Kenneth 2010). Bio-butanol is an alcohol that can be used as the direct replacement for gasoline, due to its low water miscibility, similar energy content and octane number with gasoline, blending ability with gasoline in any proportion, and its directly utilization in gasoline engine(Kumar et al 2009, Gu et al 2012). Just like second generational bio-ethanol, bio-butanol is also a renewable fuel that can be produced from lignocellulose biomass through acetone butanol ethanol (ABE) fermentation (García et al 2011).

Besides that, compare to ethanol, butanol has the following advantages (Dürre 2007):

- Bio-butanol can be directly used in pure form or blended in any concentration with gasoline, while bio-ethanol can only be blended up to 85% or used as pure form in specially designed engines.

- Regardless of using bio-butanol as pure vehicle fuel or gasoline extender, there is no need to make any modification of existing car.

- It is safer to handle, because it has a lower vapor pressure than bio-ethanol.

- It can be blended with gasoline at the refinery before storage and distribution, because it is not hygroscopic, while bio-ethanol could only blend with gasoline just before use.

- Since bio-butanol is immiscible with water, it is less likely to contaminate the groundwater if it spills; while bio-ethanol is completely miscible with water and will cause water-pollution when it spills.

- Unlike bio-ethanol, bio-butanol is less corrosive, so it can be used in infrastructure, such as pipelines, tanks, filling station, pumps, and etc.

- It has a higher mileage/gasoline blend ratio, based on its higher energy content

- Compare to bio-ethanol, bio-butanol has a more similarity quantity of the caloric value, octane number and air-fuel ratio with real gasoline, which means bio-butanol is more similar with gasoline in characteristics.

However, there still existing some issues in the productions and utilizations of bio-butanol (Jin et al 2011):

- The production of bio-butanol is quite low. The production rate of bio-butanol yield from ABE fermentation is 10-30 times lower than the bio-ethanol produce from yeast ethanol fermentation process.

- Although bio-butanol has a higher energy density than other low-carbon alcoholic biofuel, its heating value is still lower than the real gasoline or diesel fuel, so it needs to increase the fuel flow when it uses as a fossil fuel substitute.

- Bio-butanol is a kind of alcohol-based fuels, so it still cannot compatible with some fuel system components, and may cause gas gauge reading mistakes in vehicles with capacitance fuel level gauging

- Bio-butanol may yield more greenhouse gas emissions per unit motive energy extracted compare to bio-ethanol, due to it contains fewer octane number. Higher octane number means greater compression ratio and efficiency, and higher engine efficiency can achieve less greenhouse gas emissions.

- The higher viscosity of bio-butanol may lead to a potential corrosive or aggradation problem when it was used in Spark-ignition engines.

From the above illustration, we can see that although bio-butanol still need some further developments, since it still has some issue. However, compare to the other lignocellulose bio-fuel it has much more advantages, such as compatibility with infrastructure and relatively less pollution. Therefore, with further improvements or upgrade, the bio-butanol are believed to be the next generation biofuel, since it can reduce the carbon footprint, mitigate the supply and price fluctuation during the transportation sectors, relieve the energy security problem, and provide related job opportunities to improve social equality (Yue et al 2014).

References:

- Szulczyk, K.R. (2010). Which is a better transportation fuel – butanol or ethanol? International journal of energy and environment, 1 (2010) 501-512

- Sharma, B; Ingalls, R.G; Jones, C.L; Khanchi, A. (2013). Biomass supply chain design and analysis: Basis, overview, modeling, challenges, and future. Renewable and Sustainable Energy Reviews, 24 (2013) 608-627

- Cherubini, F; Strømman, A.H. (2011). Life cycle assessment of bioenergy systems: state of the art and future challenges. Bioresource Technology, 102 (2011) 437–451

- Kumar, P; Barrett, D.M; Delwiche, M.J; Stroeve, P. (2009). Methods for Pretreatment of Lignocellulosic Biomass for Efficient Hydrolysis and Biofuel Production. Industrial and engineering chemistry research, 48 (2009) 3713-3729

- Gu, X; Huang, Z; Cai, J; Gong, J; Wu, X; Lee, C. (2012). Emission characteristics of a spark-ignition engine fuelled with gasoline-n-butanol blends in combination with EGR. Fuel, 93 (2012) 611–617

- García, V; Päkkilä, J; Ojamo, H; Muurinen, E; Keiski, R.L. (2011). Challenges in biobutanol production: How to improve the efficiency? Renewable and sustainable energy reviews, 15 (2011) 964–980

- Dürre, P. (2007). Biobutanol: an attractive biofuel. Biotechnology journal, 2 (2007) 1525-1534

- Jin, C; Yao, M; Liu, H; Lee, C.F; Ji, J. (2011). Progress in the production and application of n-butanol as a biofuel. Renewable and sustainable energy reviews, 15 (2011) 4080-4106

- Yue, D; Slivinsky, M; Sumpter, J; You, F. (2014). Sustainable design and operation of cellulosic bioelectricity supply chain networks with life cycle economic, environmental, and social optimization. Industrial and Engineering Chemistry Research, 53 (2014) 4008–4029